How Graphtec Vinyl Cutters Improve Accuracy Across Every Job

When it comes to sign making, print finishing and vinyl production accuracy is everything. It’s why so many professionals rely on a Graphtec vinyl cutter as the backbone of their finishing workflow.

From the compact Graphtec CE8000 to the heavy-duty Graphtec FC9000 and the textile-focused Graphtec F-Mark 2, each machine in the range plays a distinct role in improving accuracy, productivity and confidence on the workshop floor.

Why Accuracy Matters More Than Ever

Clean edges, perfect alignment and consistent sizing across batches are now seen as standard, so even small cutting errors become obvious in the finished product.

As production speeds increase and run lengths shrink, accuracy becomes even more important. Jobs are more varied, deadlines are tighter and there is far less room for rework. This is where a Graphtec vinyl cutter truly earns its keep delivering dependable precision regardless of job size or complexity.

The Engineering Behind Graphtec Accuracy

Graphtec’s reputation is built on engineering stability. Every professional vinyl cutter in the range is designed with tight mechanical tolerances, rigid chassis construction and highly responsive servo motors. These motors allow the cutter head to move with extreme precision, reacting instantly to changes in direction and pressure.

Unlike stepper motors used in lower-cost machines, Graphtec’s servo motors maintain smooth motion throughout the entire cutting path. This results in clean corners, smooth curves and accurate tracking over long distances.

Graphtec CE8000: Precision For Day-To-Day Production

The Graphtec CE8000 is the latest generation of Graphtec’s most popular mid-range cutter. Designed for sign shops, print businesses and studios producing daily vinyl work, it delivers professional accuracy without the footprint or cost of industrial systems.

The CE8000 improves upon earlier models with faster response times, enhanced cutting force control and more refined registration accuracy. For stickers, decals, apparel film and window graphics, it tracks reliably across long jobs without drifting.

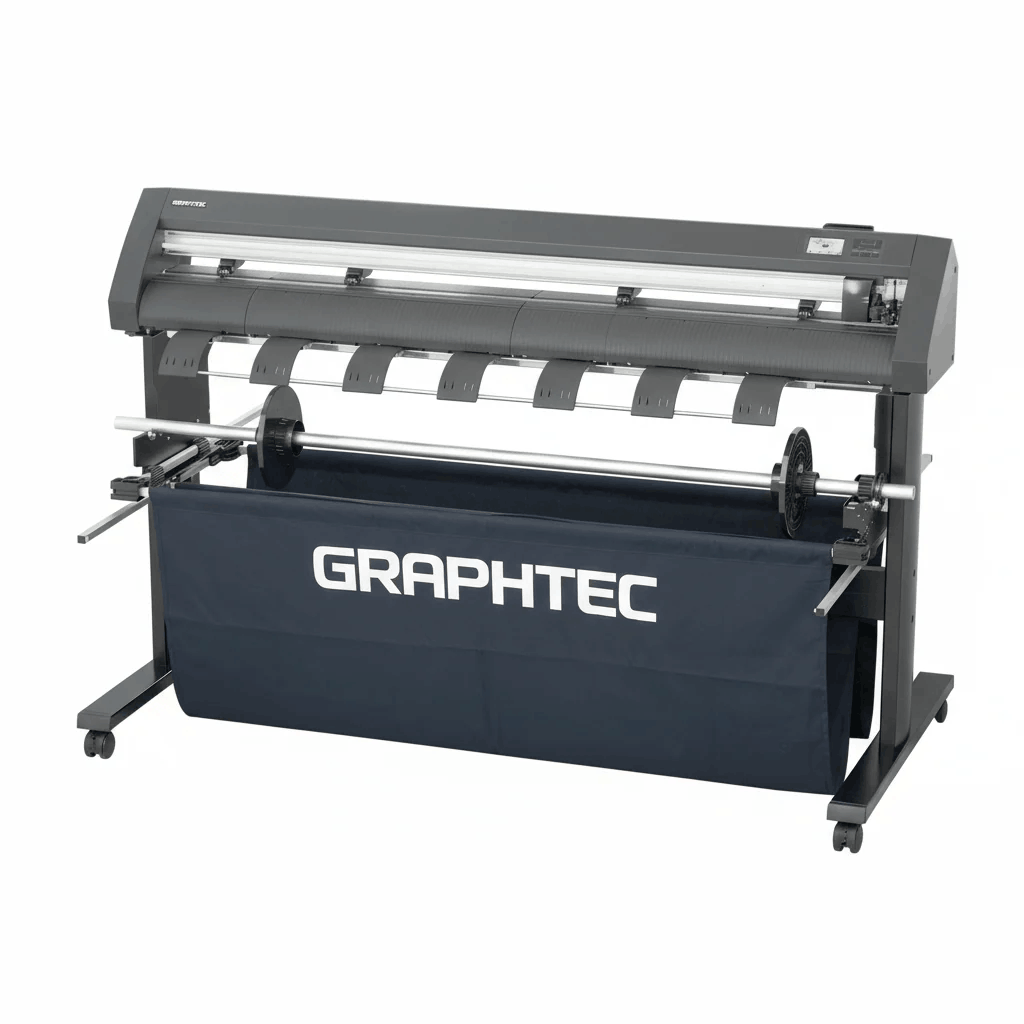

Graphtec FC9000: Industrial Accuracy At Production Scale

At the higher end of the range sits the Graphtec FC9000, designed for heavy-duty commercial environments. This machine is built for long, continuous production runs where accuracy must be maintained over metres of material at high speed.

The FC9000 uses enhanced servo drive systems, reinforced rollers and advanced media tracking to ensure consistent cutting pressure from start to finish without sacrificing speed or accuracy. This is particularly important for reflective films, thick vinyls and specialist materials used in high-end signage.

Graphtec F-Mark 2: Accuracy For Apparel And Textiles

The Graphtec F-Mark 2 is designed specifically for garment decoration and heat transfer operations. While it focuses on textiles rather than signage, accuracy is just as critical.

Heat transfer vinyl often involves layered designs, tight spacing and accurate placement on garments. The F-Mark 2 delivers the control this requires, reducing weeding errors and ensuring that fine details stay intact through pressing and application.

Registration Mark Accuracy And Print-and-Cut Workflows

One of the biggest accuracy advantages of a Graphtec vinyl cutter is its registration mark detection system. When paired with a digital printer, Graphtec cutters read printed registration marks and align cutting paths automatically.

The accuracy of this system reduces the need for manual alignment and eliminates much of the trial-and-error that slows production.

Consistency Across Batches And Repeat Orders

Another benefit of using a professional vinyl cutter is repeatability. Many businesses rely on repeat orders from customers. And those customers expect today’s reprint to match last month’s job exactly.

Graphtec cutters store cutting parameters with precision. That means the same settings can be reused for future runs without variation. Blade angle, pressure, speed and offset remain consistent, ensuring predictable results every time.

Reduced Waste And Higher Profit Margins

Accuracy directly correlates to profit. Every mis-cut panel, torn vinyl edge or misaligned sticker is wasted material. The odd sticker here or there doesn’t sound like much but over time they

soon add up. By improving cut precision, Graphtec machines significantly reduce failed cuts, weeing difficulties, reprints and operator intervention.

Your staff are also able to work more efficiently, and their output becomes more reliable.

A Better Finish Equals A Better Reputation

In the end, accuracy shows in the finished product. Clean curves, sharp corners and perfectly aligned layers all contribute to a higher-quality appearance. Customers may not understand servo motors or tracking systems, but they instantly notice when a graphic does or doesn’t look right.

Using a Graphtec vinyl cutter allows businesses to offer that level of finish consistently. Over time, this strengthens reputation, builds trust and attracts higher-value clients who expect professional-grade results rather than average-level output.

Accuracy That Grows With Your Business

Another important strength of the Graphtec range is scalability. A business might begin with a Graphtec CE8000, then add an FC9000 as volumes increase, while still running an F-Mark 2 for apparel work. Because accuracy is consistent across the range, your staff can adapt quickly without relearning cutting behaviour.

Ultimately, a Graphtec vinyl cutter delivers next-level precision through advanced servo control, stable tracking and reliable registration technology. Whether you choose the Graphtec CE8000, the Graphtec FC9000 or the Graphtec F-Mark 2, each machine is built to behave predictably, cut cleanly and protect material investment.

If you want to improve finish quality, reduce waste and deliver consistent professional results across every job, then you need a professional vinyl cutter.

For expert advice on choosing the right Graphtec system for your business, upgrading your current cutter or integrating print-and-cut finishing into your business, the team at Signmaster is ready to help. Contact Signmaster today to find the perfect Graphtec solution for your production needs.

Image source: Signmaster