Flatbed Application Tables: What You Need To Know Before Buying

When you run a small or medium-sized print business, you know that precision and efficiency are essential to keep your business running smoothly. Flatbed application tables can make a demonstrable difference to your productivity, offering a reliable way to apply graphics, vinyl, laminates and more with ease. But with so many options out there how do you know what to look for? We know a flatbed application table is an investment for your business and we want to make sure you pick the right one for your needs. Here’s what you should be looking for and why.

Why You Should Invest In A Flatbed Table

Put simply, a flatbed application table can make the process of applying laminates, graphics and mounting printed media onto various surfaces easier and faster. They reduce manual effort, improve the accuracy of applications and save time – all important when you’re up against a tight deadline.

If you’re currently applying graphics by hand, you’ll know how time-consuming and tricky this process can be to achieve a perfect, bubble-free finish. A flatbed application table solves the problem, ensuring a consistent, professional finish every time.

Key Features To Look For

Work Surface Size

Think about the size of the projects you handle most often. If most of your work is done on large format printers, you’ll need a generously sized table to support those materials. A larger table will cost more but can save you money in the long run.

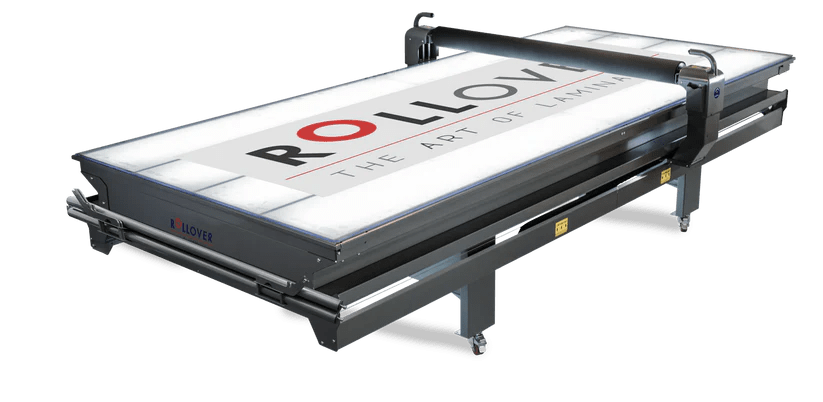

Illuminated Work Area

Some flatbed tables like the Rollover classic flatbed applicator table come with a backlit work surface which can be particularly useful if you perform a lot of close or detailed work as it makes it easier to align graphics precisely.

Ease Of Use

Look for a table with simple intuitive controls and ergonomic design features to make it easier for the operators. Simple controls will help streamline your production and mean your staff can spend more time operating it comfortably. It also means they’ll require less training to get up and running with it.

Build Quality

A sturdy, well-built table is essential for long-term use. Check for strong materials like a steel frame and high-quality rollers to ensure your investment lasts. The Rollover applicator tables boast premium grade materials and a self-healing cutting mat plus a five-year warranty should anything go wrong.

Roller Mechanism

The roller is one of the most important components of a flatbed application table, enabling easy lamination and attachment of graphics. Look for models with a smooth even roller that applies consistent pressure to prevent bubbles or wrinkles during application.

Flatbed tables come in a range of prices, from entry-level models starting at a few thousand pounds to more sophisticated models costing significantly more. While it may be tempting to go for a cheaper option a higher-quality table can more than pay for itself over time with increased efficiency and reduced waste.

If you’re still not sure if a flatbed table is right for you get in touch and our experts will talk you through the benefits.